Interview: Marcel Keuenhof on Sustainable Packaging & Waste Reduction

What are general packaging issues and why do we need product packaging at all?

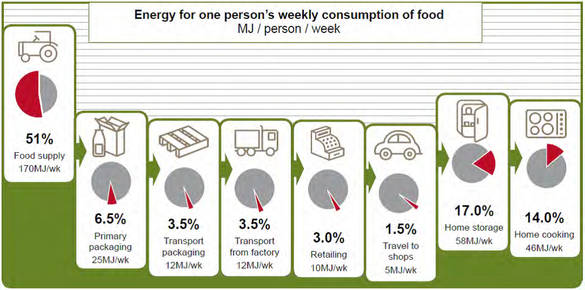

In a world were non-renewable resources become scarce, it is essential to preserve them, amongst others by striving for a circular model. Packaging is often seen as the visible waste of food, but what we forget is that its primary function is to protect the product inside during transport and handling. It should protect the food from contamination, spoilage & physical damage (breakage, discoloring, etc), maintain the quality and help avoiding food waste. Indeed, the environmental impact of packaging represents (only) a small part of the total product impact: depending on the type of food it packages, it can be as low as 1%, but on average it is around 10% (see chart).

source: INCPEN, Table for one. 2009, The Industry Council for Packaging and the Environment: Reading.

Therefore, whilst Wessanen most certainly believes in and actively works towards reduction of the environmental impact of our packaging, this should not be at the expense of the product quality, food safety and shelf life (all of which impact food waste).

Besides its environmental impact – what are further risks when it comes to product packaging?

Besides the important function of creating an actual barrier against contamination from the outside (micro-organisms, dirt, etc), packaging can also represent a chemical risk in itself, when certain components migrate into the product. When France banned the use of Bisphenol A as of beginning 2015, we took this opportunity to remove Bisphenol A from all our products sold in France but also in other countries. Absence of Bisphenol is a requirement in our policy on innovations. Another contamination from packaging material that recently came to our attention (through the authorities but also helped by a report published by Foodwatch in 2015), are the residues from (among others) printing inks in recycled paper and board. These so-called Mineral Oil Hydrocarbons have a hazardous effect on the human body and unfortunately cannot be removed completely in the paper recycling process. Therefore we are performing a risk assessment on all our packaging formats and are addressing specific issues.

Banning hazardous materials is a first step. How does this look like exactly? Are there further plans to improve Wessanen’s (product) packaging?

We have finalized our packaging policy for our innovations to address both environmental and chemical risks. This policy covers general topics like preferring recyclable material, using FSC or PEFC certified sources when recycled paper/board is not possible, reducing empty space inside the packaging and on the pallet, but also specific ones like avoiding PVC and using low-migration or bio-based/vegetable inks for printing on our packaging. In order to track our performance, we are measuring the amount of packaging material we put onto the market, expressing it as the ratio versus packed product. When we started doing this, it showed that have put 15.074 tons of packaging material on the market in 2014, which means a ratio of 0.15 kg of packaging material per kg of packed product. In 2015 we do see a significant rise in the total weight of material (19.855 tons), which is mainly due to a number of brands that Wessanen acquired that year. The more important figure in the light of sustainability, would be the packaging-product ratio, which actually dropped to 0.12 , partially due to the acquisition of the Isola Bio brand of dairy alternatives which have a low packaging-product ratio. Our goal is to further reduce this ratio through actively analysing and optimising our different packaging formats.

Product packaging is only one part. Let’s talk about waste occurring during Wessanen’s supply chain.

Waste can occur at different levels in our supply chain, anywhere between harvesting and consumption (‘from farm to fork’). For the steps that are under our direct control, we track waste levels and actively try to reduce it. Our factories apply best practices to limit waste material. For example, Abafoods and Bio Slym in Italy, dry the by-products from cereal extraction and produce animal feed out of it. Our Clipper tea site sends any waste tea (bags) to a methanisation site. Packaging material waste during production is sent for recycling as much as possible, for example broken glass jars & bottles, corrugated layer pads on pallets, plastic pallet wrapping material, and so forth. We try to reduce products that are no longer suitable for sale (out of date) to an absolute minimum. As an example, take our French warehouse for Bonneterre products: it has reduced product destruction by 50% in Q1 2015 versus the same period in 2014. If for whatever reason products cannot be sold, but they are still suitable for human consumption, we try rescuing it as much as possible by donating to food banks, for example. In 2015, we have donated equivalent of 516 k€ to food banks.

What do you think the future of product packaging will look like?

Even though developments like e-commerce and ‘the Internet of Things’ might change the look of our packaging, it is my expectation that (food) packaging overall will remain rather similar in appearance because of its primary function of transporting the product from the manufacturer to the consumer, meanwhile protecting its content from contamination, spoilage & physical damage. Other functions, like communication with the consumer, attracting their attention, displaying essential information might be more susceptible to change due to the rise of smart(er) packaging materials, printable electronics, and such. I do hope and expect that packaging solutions will have a lower environmental impact. For this we should not only look at the materials they are made of, but the sustainability of the entire foodchain, which besides packaging would also include the impact of the food itself (and food waste), transportation, refridgeration, etc. The materials themselves will be more & easier recycled, transforming from so-called down-cycling (as we see with plastic currently) to real, ‘closed-loop’ recycling. Also I expect to see more bio-based materials being developed and used, helping the industry to lower its dependancy on fossil fuel. The challenge there will be to make sure we’re not competing with the food supply of humans or animals. Finally, with the major issue of plastic ending up in our environment & oceans, I do think that we’ll reconsider and increase the focus on bio-degradability of packaging materials, even though it currently does not fit with our waste recycling infrastructure.

https://www.youtube.com/watch?v=v2ILVYJYbZA&feature=youtu.be

Bewaren

Bewaren

Bewaren

Bewaren

Bewaren

Bewaren

Bewaren

Bewaren

Bewaren